After just 18 months in business,APS recently moved to a new, roomier plantoutside St. Jerry Nevins, CEO of Applied ProductionSolutions Inc., has developed his company in avery short time. All of a sudden, we both knew that RobotStudio was the missing partof the equation. He remembers the moment well: Both Bob Etteand I could see that RobotStudio was going totake the guesswork out of the proposed newwater-jet cell installation. During the RobotStudiopresentation, Jerry saw the potential and decided to become an ABB Channel Partner. Opening the door to stabilityThe decision to let ABB play a major part was a big step for APS. Since ABBs automation software,RobotStudio, had a good reputation, Jerry decidedto invite ABB to present their new automationtechnology at the opening of his new plant. But Findlay wasnt ready to commit.He was aware that Findlays ManufacturingSystems Manager, Bob Ette, wanted to catch-upwith the competition by bringing in off-lineprogramming. TheAPS team has used RobotStudio, ABBs off-line programming software, to gain the confidence and ultimately the business ofFindlay Industries, GM Supplier of the Year, 2000. APS is a young system integrator, situated close to where the Missouri and the Mississippi meet in Americas Midwest.

#Abb robotstudio 5.14 how to

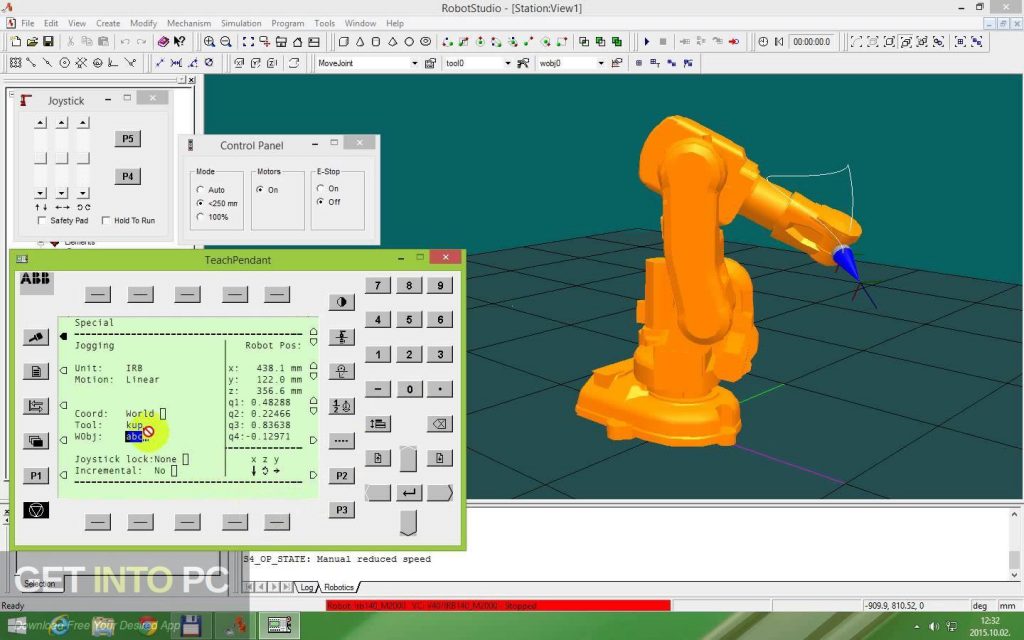

How to simulate programs 4.1 4.2 4.3 4.4 4.5 4.6 Simulation Overview.

3.10 Loading and saving programs and modules. How to program robots 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 Workflow for programming a robot. 2.7.4 Setting the local origin of an object. 2.6.3 Troubleshooting and optimizing geometries. 2.4.2 Setting up a system with track motion of type IRBTx004 manually. 2.4.1 Setting up a system with track motion of type RTT or IRBTx003 manually. Manually setting up a system with track motion. Creating a system with external axes automatically. 2.2.2 Two robot systems having different task frame positions. 2.2.1 Two robot systems sharing the same task frame position. Setting up a conveyor tracking station with two robots working on the same conveyor. How to build stations 2.1 2.2 2.3 2.4 2.5 2.6 Workflow for building a new station. 1.1.8 Libraries, geometries and CAD files. 18 1 Introduction 1.1 Terms and Concepts. ABB AB Robotics Products SE-721 68 Vsters Sweden Any other languages that are supplied have been translated from English.Ĭopyright 2008-2011 ABB.

The original language for this publication is English.

#Abb robotstudio 5.14 manual

Additional copies of this manual may be obtained from ABB. This manual and parts thereof must not be reproduced or copied without ABB's written permission. In no event shall ABB be liable for incidental or consequential damages arising from use of this manual and products described herein. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damages to persons or property, fitness for a specific purpose or the like. ABB assumes no responsibility for any errors that may appear in this manual.

The information in this manual is subject to change without notice and should not be construed as a commitment by ABB. Operating manual RobotStudio5.14 Document ID: 3HAC032104-001 Revision: GĬopyright 2008-2011 ABB. Trace back information: Workspace Main version a9 (not checked in) Published at 05:31:07 Skribenta version 785

0 kommentar(er)

0 kommentar(er)